Written By Tenaui Middle East

2021-12-26

Uncategorized

With advancements in technology, things are evolving in the printing industry. Now, more innovative and eco-friendly technologies are taking place. So, it may not surprise you that more and more businesses are transforming themselves by using UV printing!

Ultraviolet printing takes the printing industry by storm. It comes under the category of digital printing!

Basically, in traditional printing, when ink is applied on any substrate, it will dry naturally on its own. The result we get after is not so good because ink spreads unevenly. However, a naked eye can’t spot the difference. But if we see it under a microscopic level, we will understand that easily.

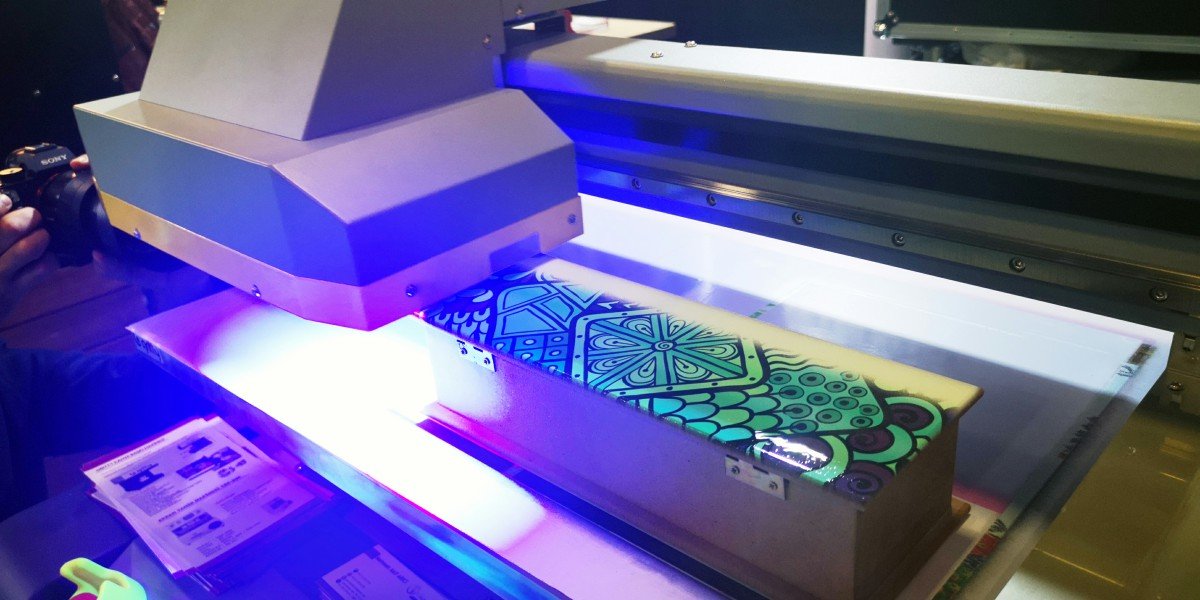

UV printing machine uses ultraviolet lights to dry the printing substrate after applying colors. The result here is more vibrant, crisp, and straightforward. Inks spread evenly, due to instant treatment of UV lights, it dried quickly, more ecofriendly.

Are you interested to learn more about this advanced printing technology? If your answer is yes, continue to read!

How Is UV Printing Different From Other Printing Methodologies?

The inks used in UV printing are better in quality than solvent-based inks. Therefore, the results of a UV printing machine are more effective than others. You can print on any surface; due to its ink and quick dry features.

For now, print anything, especially in the packaging industry, where instant results are required as materials and surfaces are limited. There is little room to change the dimensions and overall surface.

Conventional or regular printing has limited applications in terms of surfaces. For example, you can print on plastic and acrylic materials using the same old techniques. When ink is applied to a substrate in everyday printing, the solvent-based ink dries by itself after it gets absorbed in the material, and extra liquids get evaporated.

The UV printing machine drys the ink by using UV lights in UV printing. The ink dries instantly; digital images are printed on surfaces within seconds, and inks don’t absorb the surface and leave better colors. One can spot the apparent difference in terms of quality, timely delivery, and results when both images are placed side by side to each other.

Let’s break down the whole UV printing into small steps for better understanding:

- In UV printing, ultraviolet light is used to dry the ink.

- As soon as the ink is applied to any substrate, it will immediately pass through UV light.

- UV light prevents the ink from spreading unevenly on the material surface.

- Due to special ink instead of solvent-based ink, ink remains on the material surface and does not get absorbed, resulting in crisper colors.

- It can print anything on any surface due to its ability to dry instantly and no color absorption.

- As no color is evaporated in the process, it is more eco-friendly and safer for the environment.

Advanced LED UV Printing

LED UV printing is the more advanced and latest addition in this category. The UV printing machine uses LED instead of mercury lamps to dry the inks. The LEDs are a more efficient and energy-saving alternate. It also saves cost and overall period of the printing process. Leads are termed as more environmentally friendly.

LED printing is more business-friendly as it provides a unique perspective of meeting all the necessary eco principles and is more cost-effective. Due to its instant result and safety to use, many FMCG industries opt for it. Its application in food and pharmaceutical packaging is diverse and long-lasting.

VOCs (Volatile organic compounds) are less likely to emit during printing under this technology. Special inks and instant drying of ink make them achieve this green rating. Consumers also get brighter, precise, and durable colors.

Implications In Different Industries

Due to its unique features, more advance and environment-friendly inks used in UV printing machines. Ultraviolet printing provides the best solutions. It spans all industries, especially in the packaging and medicine industry.

Due to solvent-based inks, chemicals absorption on the surface of medicine packaging is harmful. The large format inkjet printers can’t print on smaller and uneven surfaces due to the ink they used and the time required for drying that ink. Therefore UV printing machine uses UV lights to dry the colors and produce more crisp and clear colors, which are more durable and hard to remove.

Especially labels on medicine packaging are more robust and hard to change, which is essential due to its sensitive nature. Similarly, its application and use in the food packaging industry are safer and more crucial for food. In routine or conventional printing, there are chances that solvent-based colors and the way they dry may contaminate the food or packaging and affect the long-term viability of the food.

Still, the introduction of LED UV printing is now safer and meets all the food packaging standards and ratings. It uses special inks which can dry up instantly with the help of LEDs, uses fewer intensity lights, and inks are not absorb in the surface and do not emit any harmful chemicals.

Diversification and Benefits of UV Printing

- UV printings replace large format inkjet printers; their diverse implications on the printing industry and materials made them more popular.

- With its broader scope, the industry can now print cost-effective, environment-friendly, and vibrant finishes in lesser time.

- It outpaces conventional printing in almost every aspect, especially energy, cost, and eco-friendly factors.

- You don’t have to wait for the ink to dry; you don’t have to remain concerned about harmful chemicals it may emit.

- No needs to worry about energy consumption. Consume less energy by using LEDs, emitting less heat, and keeping the surroundings cool.

- It saves cost and millions of work hours. Its more productive nature provides more ease and cost-effective features to its consumers.

- Color finishes are outstanding, more robust, less harmful, and can be used in any industry.

Conclusion:

Ultraviolet printing is ensuring a promising future for the print industry. Its diverse implications in different industries make it the number one choice among the industry leaders. Unlimited printing surface options make it a unique go-to solution for any surface printing. The cost-effectiveness and eco-friendly UV printing machines stand out among other available printing technologies!